Fix It Efficiently

Planned, Preventative, and Scheduled Maintenance

- Maximize Mean Time To Failure (MTTF).

- Increase uptime with planned shutdowns.

- Decrease maintenance costs.

The Problem

Maintenance managers, equipment operators, and business executives recognize the importance of preventative maintenance in maximising production capacity, and controlling costs.

- The cost of lost production from unplanned maintenance is ~10% of turnover to the average business.

- Planned maintenance costs roughly one-third what it would if unplanned.

And yet, despite the Return On Investment (ROI) to be gained, implementing a Preventative Maintenance (PM) Strategy is hard.

- It’s hard to capture and centralize run-time data for equipment.

- Without runtime data, scheduled maintenance is calendar-based.

- It’s hard to determine and administer the maintenance schedule of different equipment-classes, and types.

- It’s hard to schedule planned maintenance for production-critical assets.

The Solution

Blackhawk’s Preventative Maintenance Module, and a range of connected IoT devices.

Blackhawk’s Preventative Maintenance Module provides incremental functionality to the Reactive Maintenance Module. It gives maintenance managers and equipment operators the ability to monitor equipment remotely, with IoT devices. Data captured can be as simple as runtime and location, or more complex, like engine warnings and engine health statistics.

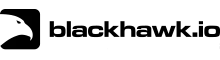

The data captured is then combined with the maintenance schedules associated with equipment. Maintenance schedules can be calendar-based or hours-based, and assigned to classes of equipment, or to individual assets.

The information generated allows maintenance managers and equipment operators to identify equipment approaching a service point, and schedule the preventative maintenance as efficiently as possible.

Define service schedules by milestone (runtime hours, mileage, schedule) and assign to assets by make and model.

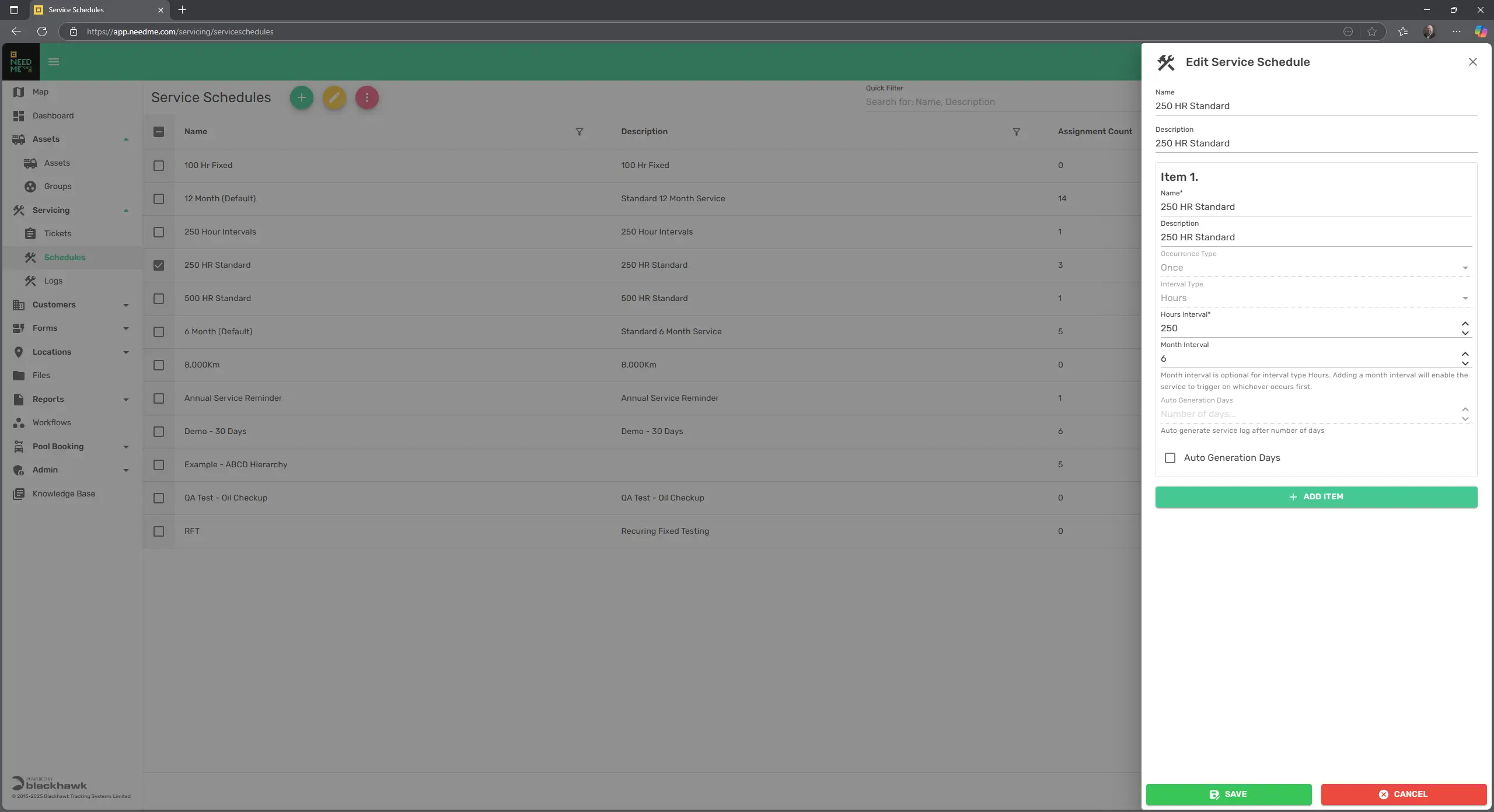

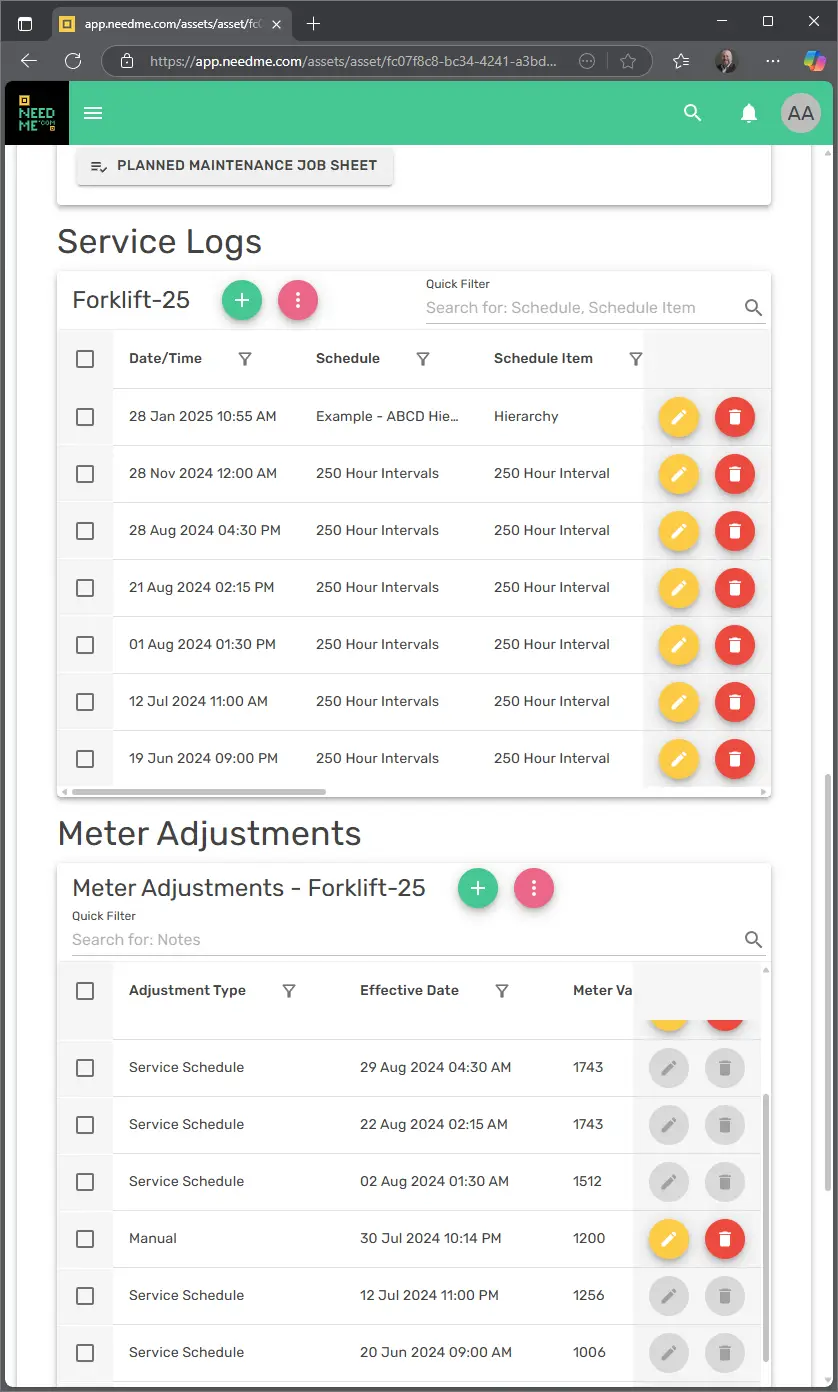

Each asset’s service history is recorded and available under its individual asset page. You can also make meter adjustments to ensure tracking hardware (such as our Easy Hour Meter) are synchronized with actual machine hours.

You can easily update Service Logs with work orders or job numbers from third party systems.

The Benefits

Higher Mean Time To Failure (MTTF)

Less unplanned downtime makes operators happy.

Lower Total Cost of Ownership (TCO)

Properly maintained equipment last longer.

Greater Visibility

Maintenance when it’s needed, not when you think it’s needed, and not when it’s broken.

Lower Costs to Maintain

Ensure that vehicles are used effectively, reducing idle time and maximizing asset value.

Tackle the Skills Shortage

Send the most junior technician capable of handling the job.

Who Benefits

Operators

Less unplanned downtime, less disruption to production.

Maintenance & Service Departments

Maintain equipment only when needed, using the most junior resource capable of doing the job.

Finance

Lower direct costs to maintain, lower opportunity costs from lost production, lower Total Cost of Ownership (TCO).